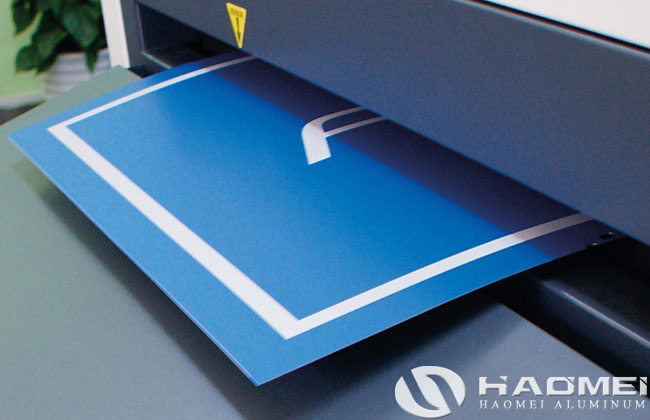

Haomei is ctp plate manufacturers who supply CTP base plate widely used in, thermal CTP, photosensitive CTP, UV-CTP and other offset printing plates. With the development of high-grade, personalized, high value-added printing industry, it is urgent to have high-end high quality CTP plate. In the production process of CTP plate, aluminum substrate plate is one of its important raw materials, and its quality directly affects the quality of CTP plate production.

The quantitative index of aluminum plate base for CTP plate includes substrate aluminum plate based chemistry, the mechanical properties of the ingredients, room temperature and baking sheet, the accuracy of thickness and width, the surface illuminance of the aluminum plate substrate, the edge burrs, and the plate shape. These indicators are related to the CTP plate production and the quality. The CTP plate substrate is usually made of aluminum with alloy grade 1145, 1150, 1060 and 1070. The temper is H state, there are three kinds of H18, H22, H26. The thickness is 0.14-0.3mm, the width is 400-1500 mm. It is supported by wooden pallet, the thickness tolerance is about 0.27 mm, and the surface roughness can't be larger than 0.30 micron.

As one of the top ctp plate manufacturers in China, Haomei have three specific requirements for the flatness of the CTP plate substrate material in production.

(1) The gap between the unrolling surface of the aluminum coil and the plane shall not be greater than 1 mm, and the number of waves per meter of unfolded surface shall not exceed 3;

(2) The side bends shall not exceed 1 mm per meter length;

(3) The aluminum plate should be compacted to the digital printing branch, the end face is neat, and no cracks or burrs are allowed.